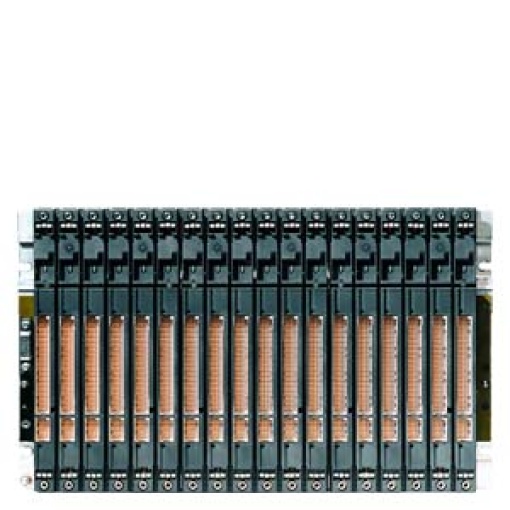

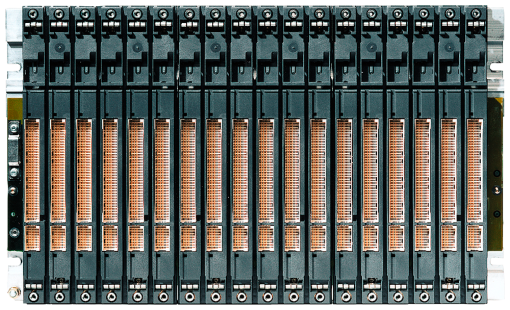

SIPLUS S7-400 rack UR1 18-slot alu based on 6ES7400-1TA11-0AA0 with conformal coating, -25…+70 °C, central and distributed with 18 slots, 2 redundant PS can be plugged in The SIPLUS extreme variant also protects the automation system components from harsh ambient conditions, such as extremely high and low temperatures, corrosive gases, condensation, frost and biologically, chemically and physically active substances that can occur in control cabinets or container solutions in the production area. This also reliably protects your challenging automation tasks and provides additional investment security.

Programmable Logic Controllers and Dialogue Terminals

SIPLUS S7-400 UR1 With 18 slots, aluminum -25 ... 70 C with conformal coati...

Nortécnica Ref:

EAN:

4042948599129

Description

Technical Information

Attributes

Width

482.5

Height

290

Depth

27.5

Suitable for safety functions

No

Type of voltage input voltage

DC

Number of slots

18

Redundancy

No

With integrated power supply

No

Suitable for rail mounting

Yes

Explosion safety category for gas

ATEX gas-ex-protection, Cat. 3G

Explosion safety category for dust

None

Appendant operation agent Ex ia

No

Appendant operation agent Ex ib

No

Output voltage AC 50 Hz

-

Output voltage AC 60 Hz

-

Output voltage DC

-

Front built-in possible

No

Rack-assembly possible

Yes

Wall mountingdirect mounting

Yes

Input voltage AC 50 Hz

-

Input voltage AC 60 Hz

-

Input voltage DC

-

Max. output current AC 50 Hz

-

Max. output current AC 60 Hz

-

Max. output current DC

-

Max. input current AC 50 Hz

-

Max. input current AC 60 Hz

-

Max. input current DC

-

Performance level according to EN ISO 13849-1

-

Type of output voltage

DC

SIL according to IEC 61508

-

Brands

SIEMENS

Long Description

SIPLUS S7-400 rack UR1 18-slot alu based on 6ES7400-1TA11-0AA0 with conformal coating, -25…+70 °C, central and distributed with 18 slots, 2 redundant PS can be plugged in The SIPLUS extreme variant also protects the automation system components from harsh ambient conditions, such as extremely high and low temperatures, corrosive gases, condensation, frost and biologically, chemically and physically active substances that can occur in control cabinets or container solutions in the production area. This also reliably protects your challenging automation tasks and provides additional investment security.